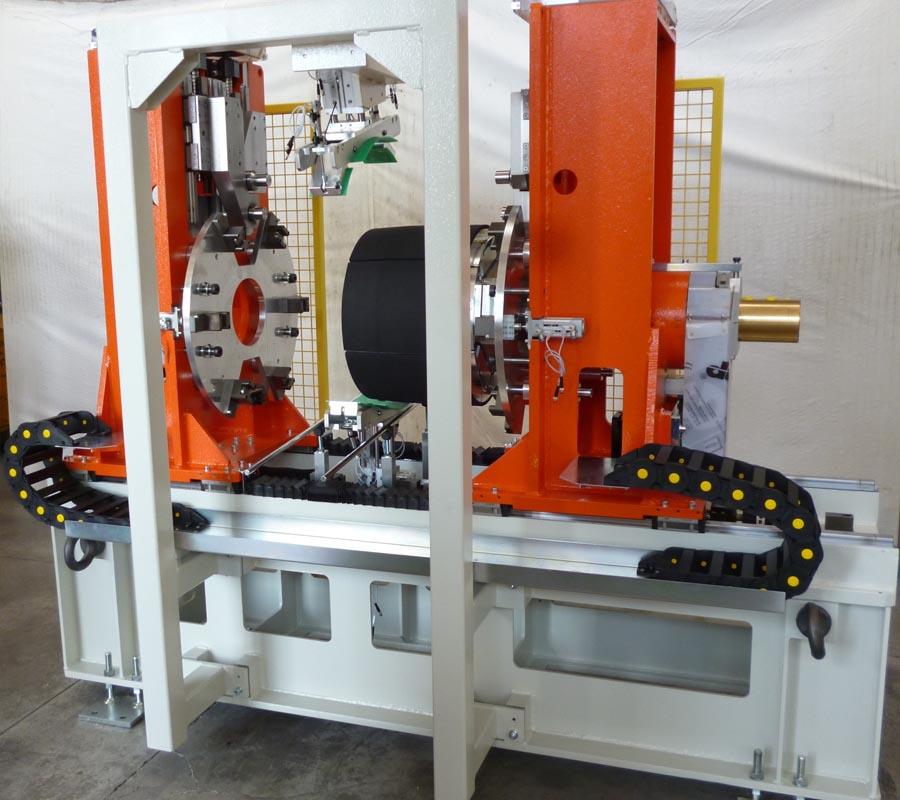

Automatic washing machine basket edging machine

Industrial automation for the household appliances sector

The machine has a production capacity of about 60 baskets per hour.

The basket is loaded manually by the operator: the basket is placed on the positioning system located in the center of the machine, which facilitates the insertion of the self-centering spindle. The operator closes the doors and starts the work cycle, the left head, with integrated self-centering spindle, moves by introducing the spindle into the basket. The locking system is activated and the basket is anchored. Subsequently the head on the right moves closer to the basket, at this point the rim riveting wheels close on the external profile of the basket, the rotation of the spindle allows the shaping of the external sheet of the basket creating a rounded profile.

Once the operation is complete, the riveting wheels reopen, the spindle releases its grip on the basket and the heads return to their initial position, at this point the basket rolls along the rear discharge chute.

The machine is completely programmable via the operator keyboard, it is possible to set the size of the border and if it is to follow it on one side only or both, it is possible to create programs dedicated to the various models and create a database.

Optionals can be applied to the machine, such as, for example, an anthropomorphic robot can be applied to increase productivity, eliminating the presence of the operator.

Our Adaptive Industrial Automations Guaranteed to measure

No risk with our A.I.A.G.Protocol

All our automations are 100% guaranteed

Request information

Tonelli Macchine S.r.l.

Via Giovanni Agnelli 8/C

61030 Lucrezia di Cartoceto (PU) Italy

Phone +39 0721 855055

Fax +39 0721 854095

info@tonellimacchine.com

Tonelli Macchine S.r.l. | P.IVA 02107050417 Business Register of Pesaro Urbino N° 02107050417 N.R.E.A. 154868 Share capital € 15.000,00 i.v.